Miniature Circuit Breakers: Types, Uses and Consideration Tips

Considering upgrading the electrical installation in your home or business? Start with the basics. Electrical protection devices, including circuit breakers and newly-mandated residual circuit breakers (RCBs), are essential in protecting residents, employees and equipment from electrical shock, power surges, overloads and electrical fires. They’ve come to replace older and less reliable fuses to offer improved protection, faster operation and to safeguard the reliability and efficiency of home and business.

Contents

Miniature Circuit Breaker Basics

Circuit breakers differ from fuses in multiple ways. Both devices are tasked to cut the power supply in the event of an electrical fault. Compared to fuses, which must be replaced after every power outage or electrical surge, reliable and well-designed miniature circuit breakers or MCBs can be reactivated with a simple flick of a switch.

This convenience is also paired with improved protection. Fuses protect only against power overloads. Circuit breakers, however, go one step further to also include protection in the event of a short circuit. This means more comprehensive coverage, protecting the entire electrical installation rather than separate circuits and connected devices.

How MCBs Work

To understand why MCBs are the preferred tripping protection device, let’s consider the parts that constitute a circuit breaker and how they work as a unit. A circuit breaker has two key ratings: the current it can carry during normal use and the maximum fault current it can safely interrupt to protect the wiring. It does this by tripping when the current exceeds its limit, using a mix of internal and external parts.

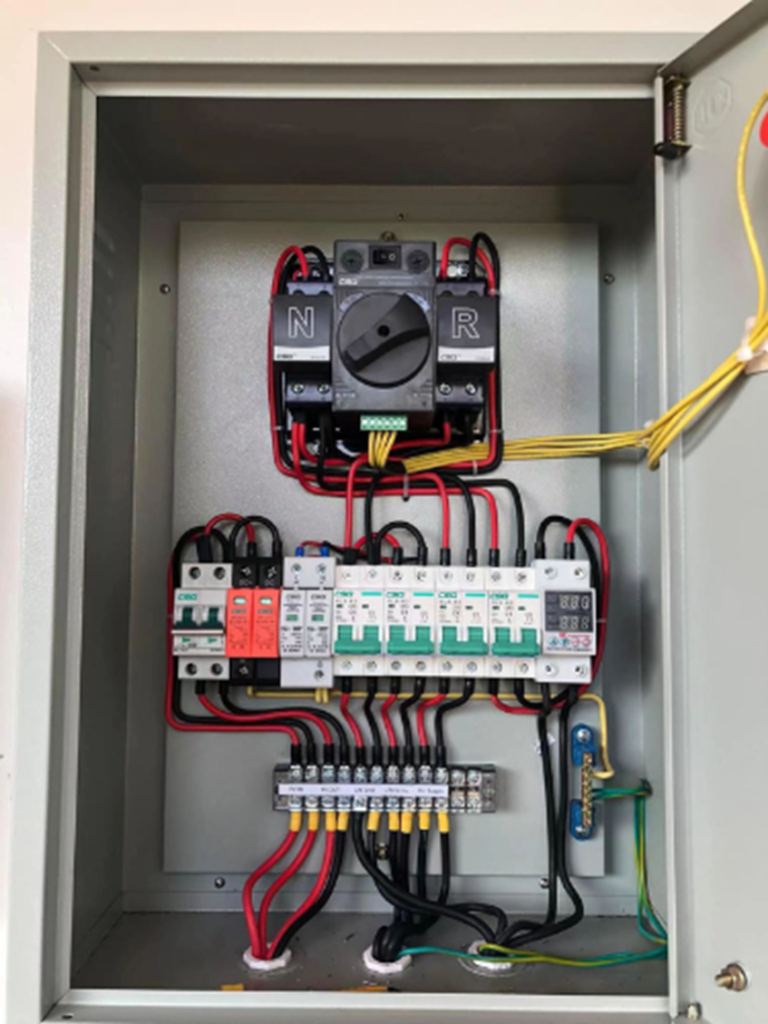

The outer housing made of moulded insulative material encloses internal elements and prevents electrical shock. The circuit breaker is connected to incoming and outgoing wires via pieces of conductive metal that make up the terminals. Opening and closing the circuit is achieved with an activation switch. This has three positions (‘on’, ‘off’ and ‘tripped’), with the tripped position indicating a current overload. Other external components are the DIN rails, used to mount the miniature circuit breaker in the panel box.

Inside is where all the magic happens. This includes internal contacts or the two metallic pieces that move to close or open (or ‘break’) the circuit, with one contact connected to the actuator mechanism and the other to the main panel. An internal actuator mechanism, with a metal arm with one end connected to the circuit breaker switch and the other to a contact.

Flipping the switch upwards in the ‘on’ position forces the contacts together. Flipping it down in the ‘off’ position causes the actuator mechanism to pull the contacts apart. Actual tripping is done by the tripping unit. This is the component that activates the actuator mechanism during overloads or short circuits. Most tripping units are of the hybrid type, consisting of both bi-metallic strips typical of thermal mechs (efficient in overloads) and electromagnetic solenoids for protection in short circuits.

Currently can freely pass with the switch set to the on position, ensuring a reliable power supply. During an overload, the bi-metallic strip in the trip unit overheats and bends, automatically opening the circuit to cut off power. Similarly, during a short circuit and power surge, the internal coil in the electromagnetic solenoid creates a strong magnetic field to separate the contacts and cut power.

Types of Miniature Circuit Breakers

There are several types of MCBs, each differing in the ‘trip curve’ or how quickly the breaker trips the circuit during an overload. This allows selecting breakers suitable for different applications. The most common types are:

- Type B: These trip at 3 to 5 times their rated current. This high sensitivity means they’re the preferred type in low-current settings, such as homes.

- Type C: These trip at 5 to 10 times their rated current, or in moderate surges. Type C circuit breakers are common in high-current applications, such as commercial settings and smaller industrial machinery.

- Type D: Type D breakers are designed to trip at 10 to 20 times their rated current, making them suitable for high inrush current typically seen in transformers, large motors, welding equipment and other high-current applications.

The list is complemented by Type K with similar current sensitivity to Type C breakers but faster tripping times, and Type Z breakers to protect extremely sensitive circuits, such as those powering electronics.

Choosing the Right Breakers

There are several factors to consider when setting out to buy circuit breakers. This includes:

- Current rating: Current ratings should be correctly matched to the circuit’s load. This avoids unwanted tripping and ensures a safe yet stable power supply. As a rule of thumb, calculate the circuit’s total load and add a safety margin of 10 to 25 percent.

- Breaking capacity: This is the maximum amount of current a breaker can interrupt during overloads, surges, and short circuits without damage. Higher capacity MCBs are generally used in industrial or commercial systems where potential fault currents are larger. Residential systems typically use standard capacity breakers, with capacities averaging below 6kA.

- Tripping curve: Basically, the type of circuit breaker is classified according to tripping times and the overloads that cause them to trip. These are described above.

- Number of poles: Select the number of poles based on circuit requirements. Single-pole MCBs have one switch and protect a single phase of the circuit. A double-pole circuit breaker has two switches and protects two phases and a neutral connection. These are more common in residential and small commercial use. Three-pole variants can break the current on all three circuits, while four-pole types are used in unbalanced circuits and contain four switches, three phases, and a neutral. They are seen in high-voltage, three-phase industrial applications.

Sorry, the comment form is closed at this time.